we specialize in rapid prototyping, CAD modeling, CFD simulations, process design, and hydrogen fuel cell development. Whether you’re an entrepreneur with a new product idea, a researcher looking for functional prototypes, or an industry leader needing precision-engineered solutions, we provide the speed, accuracy, and innovation required to bring your vision to life.

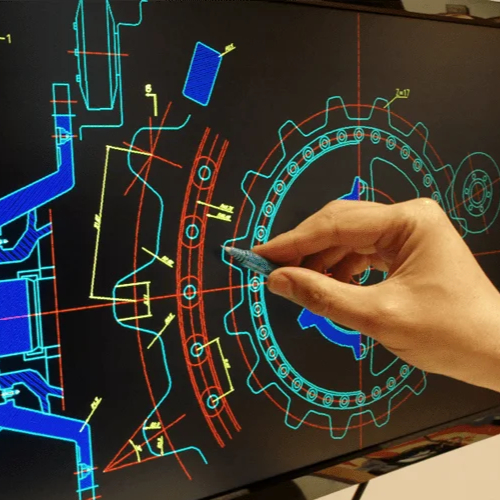

Bring concepts to life with advanced CAD design and seamless modeling.

Enhance efficiency and decision-making with smart industrial automation

Enhance efficiency with intelligent process design and optimization

We create functional prototypes, concept models, and 3D-printed parts for industrial applications, product testing, and design validation.

We provide a variety of materials, including plastics (PLA, ABS, PETG), resins, and metals, depending on the application and mechanical properties required.

The timeline depends on complexity, material, and size, but we typically deliver prototypes within 3-10 days after finalizing the design.

Yes, we provide DFM (Design for Manufacturability) consulting, ensuring that prototypes are optimized for mass production and performance.

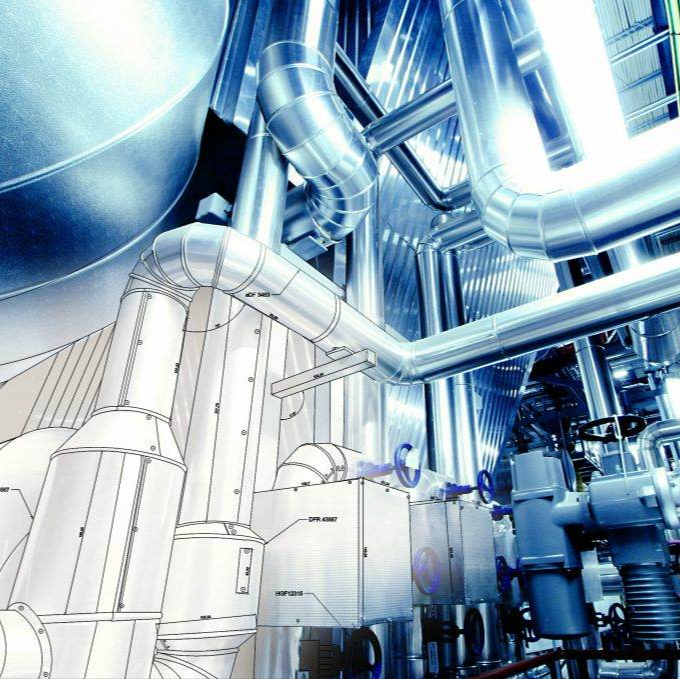

We provide for fluid flow, pressure simulations & heat transfer, mainly for hydrogen-related applications.

CFD helps identify inefficiencies, optimize designs, reduce prototyping costs, and enhance energy efficiency in industrial processes, HVAC systems, hydrogen technologies, and automotive/aerospace applications.

We use industry-leading tools like ANSYS Fluent, COMSOL & CATIA with FloEFD from Dassault Aerospace depending on the project requirements and complexity.

Yes, we can optimize geometries based on experimental validation by comparing with simulation results.

We tailor the process design to your industry’s unique needs, taking into account factors such as production volume, materials used, energy efficiency, and any industry-specific regulations to create the most effective layout and workflow.

Our approach includes analyzing potential costs, identifying areas for energy optimization, minimizing waste, and recommending automation or alternate solutions to reduce operational costs while maintaining productivity.

Yes, we assist with machine selection, ensuring that the equipment is suitable for your production needs, within budget, and capable of scaling as your factory grows. We also provide guidance on suppliers and manufacturers for these machines.